The Kreutzalox® products

For wet and dry grinding with Al2O3 contents of 92%, 95% and >99%, other grades on request.

The most important Kreutzalox® products include grinding balls and cylinders in various sizes. Kreutz GmbH manufactures moulded bricks and mosaic tiles as wear protection for mills, funnels and pipes.

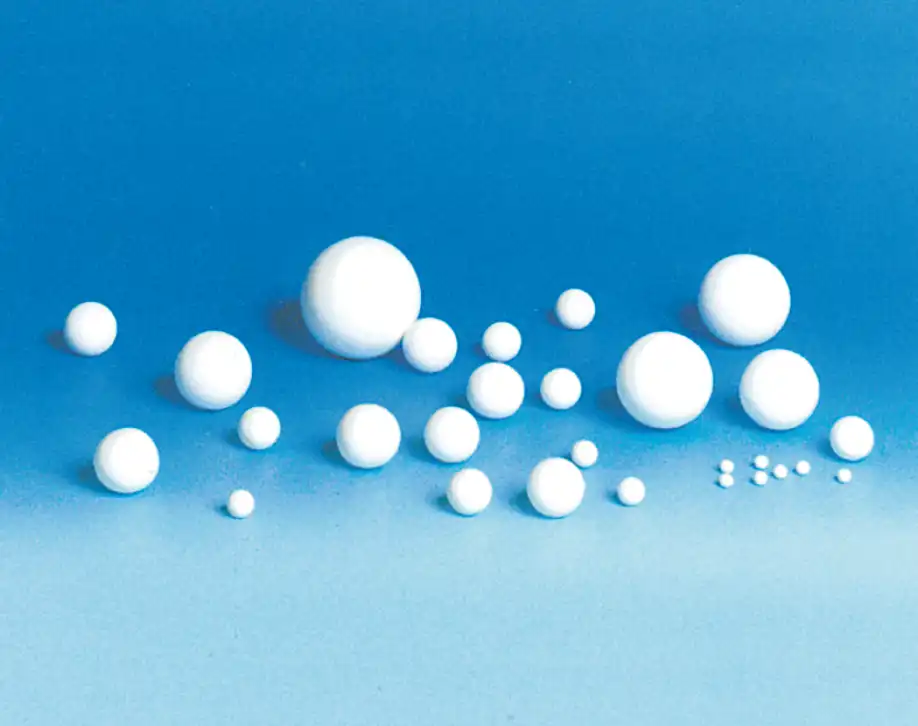

The standard grinding balls are available in diameters of 7 to 63 mm and the grinding cylinders 15 to 45 mm.

Grinding balls

Grinding balls for effective non-ferrous grinding of zircon, rutile, quartz, aluminium oxide, corundum, enamel frits, ceramic frits and other materials.

Technical Data (PDF)

| KREUTZALOX 92 | KREUTZALOX 95 | KREUTZALOX 99,5 | KREUTZALOX 99,7 | |

| Al2O3 | 92 % | 95 % | 99,5 % | 99,7 % |

| SiO2 | 3,50 % | 2,20 % | 0,03 % | 0,03 % |

| MgO | 2,35 % | 1,40 % | 0,15 % | 0,12 % |

| CaO | 1,90 % | 1,10 % | 0,02 % | 0,03 % |

| Na2O | < 0,20 % | < 0,20 % | < 0,1 % | < 0,1 % |

| Fe2O3 | < 0,50 % | < 0,50 % | < 0,1 % | < 0,1 % |

| Specific gravity/density | > 3,60 g/cm3 | > 3,69 g/cm3 | > 3,75 g/cm3 | > 3,75 g/cm3 |

| Water absorption | 0% | 0% | < 0,4 % | < 0,4 % |

| Hardness Mohs | ~ 9 | ~ 9 | ~ 9 | ~ 9 |

| Colour | white | white | white | white |

| Stability of temperatur | until 1.300 °C | until 1.300 °C | until 1.300 °C | until 1.300 °C |

| diameter | KREUTZALOX 92 | KREUTZALOX 95 | KREUTZALOX 99,5 | KREUTZALOX 99,7 |

| 7 mm – 1/4“ | ● ● ● | ● ● ● | ||

| 12 mm – 1/2“ | ● ● ● | ● ● ● | ||

| 20 mm – 3/4“ | ● ● ● | ● ● ● | ● ● ● | |

| 25 mm – 1“ | ● ● ● | ● ● ● | ● ● ● | ● ● ● |

| 30 mm – 1 1/4“ | ● ● ● | ● ● ● | ● ● ● | |

| 35 mm – 1 3/8“ | ● ● ● | ● ● ● | ● ● ● | |

| 40 mm – 1 1/2“ | ● ● ● | ● ● ● | ||

| 45 mm – 1 3/4“ | ● ● ● | ● ● ● | ||

| 50 mm – 2“ | ● ● ● | ● ● ● | ||

| 63 mm – 2 1/2“ | ● ● ● | ● ● ● |

● ● ● standard ● ● ● special sizes by inquiry

Grinding cylinders

Grinding cylinders for effective non-ferrous grinding of zircon, rutile, quartz, aluminium oxide, corundum, enamel frits, ceramic frits and other materials.

Technical Data (PDF)

| KREUTZALOX 92 | KREUTZALOX 95 | KREUTZALOX 99,5 | |

| Al2O3 | 92 % | 95 % | 99,5 % |

| SiO2 | 3,50 % | 2,20 % | 0,03 % |

| MgO | 2,35 % | 1,40 % | 0,15 % |

| CaO | 1,90 % | 1,10 % | 0,02 % |

| Na2O | < 0,20 % | < 0,20 % | < 0,1 % |

| Fe2O3 | < 0,50 % | < 0,50 % | < 0,1 % |

| Specific gravity/density | > 3,60 g/cm3 | > 3,69 g/cm3 | > 3,75 g/cm3 |

| Water absorption | 0% | 0% | < 0,4 % |

| Hardness Mohs | ~ 9 | ~ 9 | ~ 9 |

| Colour | white | white | white |

| Stability of temperatur | until 1.300 °C | until 1.300 °C | until 1.300 °C |

| Flexural strength | > 340 N/mm2 | > 340 N/mm2 | > 300 N/mm2 |

| Compressive strength | > 2.250 N/mm2 | > 2.250 N/mm2 | > 1.750 N/mm2 |

| diameter | KREUTZALOX 92 | KREUTZALOX 95 | KREUTZALOX 99,5 |

| 13 mm – 1/2“ | ● ● ● | ● ● ● | ● ● ● |

| 15 mm – 5/8“ | ● ● ● | ● ● ● | ● ● ● |

| 20 mm – 3/4“ | ● ● ● | ● ● ● | ● ● ● |

| 25 mm – 1“ | ● ● ● | ● ● ● | |

| 30 mm – 1 1/4“ | ● ● ● | ● ● ● | |

| 35 mm – 1 3/8“ | ● ● ● | ● ● ● | |

| 40 mm – 1 1/2“ | ● ● ● | ● ● ● | |

| 45 mm – 1 3/4“ | ● ● ● | ● ● ● |

● ● ● standard ● ● ● special sizes by inquiry

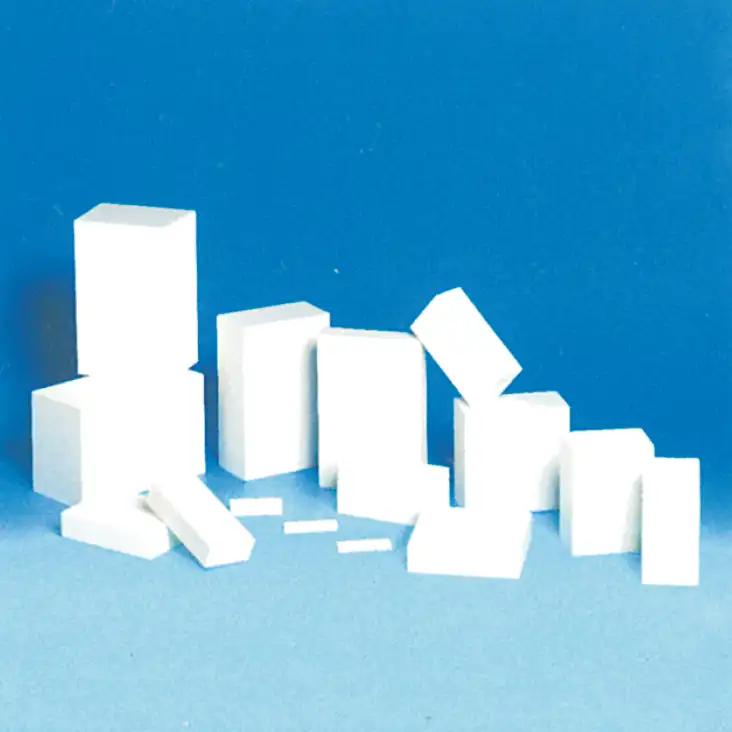

Lining bricks

Moulded bricks as wear protection for mills, mixers, funnels, slides and other components.

Different formats are available. We can also manufacture customer-specific sizes to order.

Technical Data (PDF)

| KREUTZALOX 92 | KREUTZALOX 95 | |

| Al2O3 | 92 % | 95 % |

| SiO2 | 3,50 % | 2,20 % |

| MgO | 2,35 % | 1,40 % |

| CaO | 1,90 % | 1,10 % |

| Na2O | < 0,20 % | < 0,20 % |

| Fe2O3 | < 0,50 % | < 0,50 % |

| Specific gravity/density | > 3,60 g/cm3 | > 3,69 g/cm3 |

| Water absorption | 0% | 0% |

| Hardness Mohs | ~ 9 | ~ 9 |

| Colour | white | white |

| Stability of temperatur | until 1.300 °C | until 1.300 °C |

| KREUTZALOX 92 | KREUTZALOX 95 | ||

| Measurements | Weight | Rectangular bricks | Rectangular bricks |

| 155 x 100 x 75 mm | ca. 4.300 g | ● ● ● | ● ● ● |

| 155 x 100 x 70 mm | ca. 4.100 g | ● ● ● | ● ● ● |

| 155 x 100 x 52 mm | ca. 2.850 g | ● ● ● | ● ● ● |

| 155 x 100 x 25 mm | ca. 1.400 g | ● ● ● | ● ● ● |

| 155 x 100 x 12,5 mm | ca. 670 g | ● ● ● | ● ● ● |

| 155 x 100/95 x 52 mm | ca. 2.850 g | ● ● ● | ● ● ● |

| 100 x 100 x 52 mm | ca. 1.940 g | ● ● ● | ● ● ● |

| 100 x 100 x 25 mm | ca. 860 g | ● ● ● | ● ● ● |

| 100 x 100 x 12,5 mm | ca. 440 g | ● ● ● | ● ● ● |

| 100 x 75 x 52 mm | ca. 1.360 g | ● ● ● | ● ● ● |

| 100 x 75 x 25 mm | ca. 700 g | ● ● ● | ● ● ● |

| 100 x 50 x 52 mm | ca. 860 g | ● ● ● | ● ● ● |

| 100 x 50 x 25 mm | ca. 470 g | ● ● ● | ● ● ● |

Tolerances according to DIN 40680-Teil 1. Middle

● ● ● standard ● ● ● special size by inquiry

Spray granulate

Spray granulate to manufacture building components and moulded bodies according to the dry pressing process. We produce spray granulates with Al2O3 contents of 92 – 99.5% as well as customer-specific special masses.

Our plants can also be used to prepare and spray dry ceramic masses to our customers’ requirements.

Technical Data (PDF)

| Typical chemical analysis |

KREUTZALOX SPG 92 | KREUTZALOX SPG 95 | KREUTZALOX SPG 96 | KREUTZALOX SPG 97 | KREUTZALOX SPG 98 | KREUTZALOX SPG 99,5 | KREUTZALOX SPG 99,7 |

| Al2O3 (%) | 92 | 95 % | 96 % | 97,4 % | 98,20 % | 99,50 % | 99,7 % |

| SiO2 (%) | 3,5 | 2,20 % | 2,70 % | 1,50 % | 0,94 % | 0,03 % | 0,03 % |

| MgO (%) | 2,35 | 1,40 % | 0,20 % | 0,8 % | 0,15 % | 0,15 % | 0,12 % |

| CaO (%) | 1,90 | 1,10 % | 0,30 % | 0,1 % | 0,57 % | 0,02 % | 0,03 % |

| Na2O (%) | < 0,20 % | < 0,20 % | < 0,20 % | < 0,2 % | < 0,1 % | < 0,1 % | < 0,1 % |

| Fe2O3 (%) | < 0,50 % | < 0,50 % | < 0,50 % | < 0,5 % | < 0,1 % | < 0,1 % | < 0,1 % |

| Unit | KREUTZALOX SPG 92 | KREUTZALOX SPG 95 | KREUTZALOX SPG 96 | KREUTZALOX SPG 97 | KREUTZALOX SPG 98 | KREUTZALOX SPG 99,5 | KREUTZALOX SPG 99,7 |

| Primary cristall size d50 μm | 2,5 ± 0,5 | 2,5 ± 0,5 | 2,5 ± 0,5 | 2,5 ± 0,5 | 2,5 ± 0,5 | 0,6 ± 0,3 | 0,6 ± 0,3 |

| bulk density (g/l) | 1.190 – 1.250 | 1.190 – 1.250 | 1.190 – 1.250 | 1.220 – 1.260 | 1.220 – 1.260 | 1.200 – 1.300 | 1.200 – 1.300 |

| grain size distribution > 0,4 mm (%) | max. 3 | max. 3 | max. 3 | max. 3 | max. 3 | max. 3 | max. 3 |

| grain size distribution 0,25-0,4 mm (%) | 25 – 40 | 25 – 40 | 25 – 40 | 25 – 40 | 25 – 40 | 25 – 40 | 25 – 40 |

| grain size distribution 0,1-0,25 mm (%) | 55 – 70 | 55 – 70 | 55 – 70 | 55 – 70 | 55 – 70 | 55 – 70 | 55 – 70 |

| grain size distribution < 0,1 mm (%) | max. 15 | max. 15 | max. 15 | max. 15 | max. 15 | max. 15 | max. 15 |

| sinter-temperatur (°C) | ~ 1.500 | ~ 1.530 | ~ 1.530 | ~ 1.530 | ~ 1.530 | ~ 1.600 | ~ 1.600 |

| density (g/cm3) | > 3,60 | > 3,69 | > 3,69 | > 3,69 | > 3,69 | > 3,75 | > 3,75 |

The mentioned values are to be understood as standard values.