70 yıl Kreutz Mahlwerke

Non-ferrous milling, contract processing and the production of oxide ceramics are parts of the business area of Helmut Kreutz GmbH.

The company was established in Haiger-Langenaubauch (Germany) in 1953 by Helmut Kreutz. As a medium-sized business, Kreutz is specialised in the non-ferrous milling and processing of raw materials as well as the production of hard-wearing oxide ceramics such as grinding medias and linings. As a leading grinding factory, Kreutz supplies clients in the ceramics industry all over the world with micronized zirconium silicate. In addition to the processing of zirconium, the milling of aluminium oxide, ceramic frits, quartz powder with a very low iron content and many other materials for companies working with ceramics, fire-resistant materials, paints and varnishes are substantial areas of the Kreutz product portfolio.

The introduction of an integrated environmental and energy management system in accordance with DIN EN ISO 14001 and DIN EN ISO 50001 binds the Kreutz business policy to minimise its environmental impact and to reduce the specific energy consumption of this energy-intensive company.

The 1950s: Venturing into the ceramics sector

The first aim after founding the company in the 1950s was to market a red-firing slate from an own quarry as raw material for terrazzo plates and window sills. Investigations in the year 1956 showed that the “Langenaubacher Kreutz clay” was also very suitable for use as ceramic. It has a high aluminia content and a good plasticity as clay as well as very favourable characteristics for glazing.

Thus, it was possible to produce cast and glazed decorative items in the factory that are still very popular with collectors today. Potential clients for milled clay were based in Westerwald so that the introduction of the company to the ceramic sector was successful. Today, approx. 2000 t of clay slate are still recovered per year for special applications.

The 1960s: The first industrial plant for non-ferrous dry milling

Custom milling became increasingly important in the 1960s. Zirconium silicate, ceramic frits and enamel was milled. It was because of this procedure that Helmut Kreutz came in contact with Degussa. Subsequently, a development partnership was established during which a continuous, non-ferrous dry milling process was developed. The first plant for this purpose was commissioned in 1965.

The requirements of the market, however, continued to increase. Finer, more micronized qualities were demanded especially for zirconium silicate in order to make it more efficient when used as opacifier. Therefore, the technology of the system had to be further developed. The Kreutz mill works were hugely interesting for other clients, as non-ferrous milling was possible. More and more contract orders followed for hard materials such as rutile, ilmenite, aluminium oxide, quartz, feldspar and recycling materials such as glass trough rubble, porcelain rubble, etc. to name just a few. These different industrial minerals and reclaims made it necessary to introduce several, independent production lines in order to avoid contamination. For processing of rubble materials, it was possible to use the primary crushers and granulators for production to ensure different grain sizes and milling fineness.

Milling of aluminia, ceramic frits and very light quartz was also established as an important aspect of the Kreutz mill works.

Since 2006, the processing water necessary to cool the mills has been obtained from a deep well dug by Kreutz.

Ticaret fuarı videosu

Tarih

1953

Helmut Kreutz’un kurduğu

1953

Terrazzo yongalarının üretimine başlandı. (Arka planda fabrika). Ön tarafta yeni inşa edilen ofis binasını görüyorsunuz.

1974

Şirket şu anda iki granülasyon tesisi ve sekiz öğütme tesisini giderek artan bir başarıyla işletiyor.

2023

Şirketimiz bugün tüm üretim tesislerimiz, ofis ve laboratuvar tesislerimizle hizmet vermektedir.

Kreutzonit- Zirkonsilikate

The continuous increase of production quantities and the on-going development of production technologies and quality standards make Kreutz an important player for contract milling and processing of raw mineral materials today. One of the most important business areas of the Kreutz mill works is the micronization of zirconium silicate.

Successful product development together with clients

The milling and crushing systems are often used by customers for contract processing. This also includes the recycling of raw materials. Also wet-milling and spray drying is also used for the production of client-specific masses. The kilns for the production of oxide ceramic are often used for contract calcination or firing. All necessary quality controls are carried out in the internal laboratories. Modern laser granulometers and other equipment are available here to ensure reproducible measurements even on the micron scale. Further tests such as chemical or X-ray analyses are performed under collaboration with certified institutes.

Product development together with clients is always possible and products were often successfully placed on the market in the past.

The clients’ requirements are always paramount for Kreutz.

Hard-wearing grinding medias

The usage of aluminia grinding medias continuously increased by installation of further milling systems, today 20 milling systems are available. Acquisition became more difficult due to long lead times and fluctuating quality so that the company started to produce its own grinding medias in the beginning of the 1980s. Initially, a rotary tablet press and a high-temperature kiln were bought.

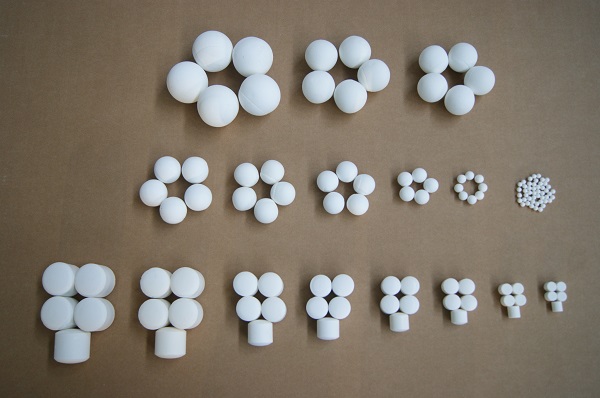

In the following years, on-going development of the mass recipe and processing equipment resulted in qualities that were suitable for internal use but also found interested buyers in the ceramics industry. An oxide portfolio was created that is optimised in terms of a very low wear. Thus, milling bodies in form of balls and cylinders with specially rounded caps as well as linings for mills and wear protections are made today. The quality range includes standard products with an aluminium oxide content of 92 % as well as special products with an aluminia content up to 99.7 %. The development activities today focus especially on high-quality materials.

Due to the production of products with standard quality in Asia and the associated pricing pressure, it is becoming more and more difficult to produce cost-effective grinding medias for standard milling tasks in Europe. Therefore, the aim is to further improve the quality and to offer client-specific grinding medias that are optimised e.g. for the addition of SiO2 during milling.

Kreutz can, of course, also process and spray-dry ceramic mixtures according to client requirements.

Kreutzalox-Produkte

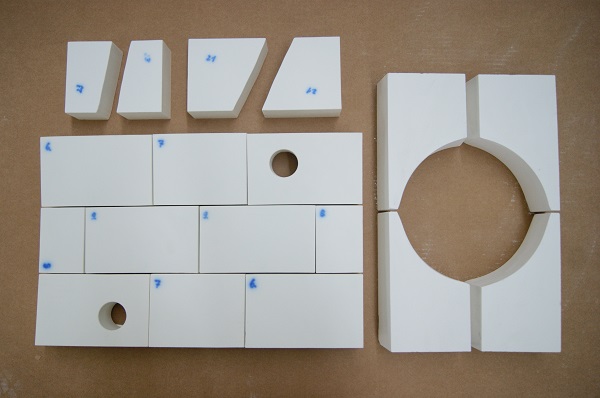

In addition to grinding medias, lining bricks and plates are also important for wear protection. These are used in drum mills for non-ferrous milling as well as in slides and funnels.

In addition to the production of hard-wearing qualities, the service is also becoming more important. Complete installation of a new lining including all necessary materials often has to be provided by one supplier. Thus, Kreutz can offer the engineering part but also installation. When lining a new mill, we begin e.g. by removing the old lining and continue with sandblasting of the metal surfaces as well as the installation of the new lining. For this purpose, a high-performing epoxide resin glue with a maximum long-term heat resistance of 150 °C developed under collaboration with Kreutz can also be used.

The Kreutzalox products are offered in standard qualities with an aluminium oxide content of 92 %, 95 % and >99 %. Furthermore, other qualities are possible upon demand, e.g. spray granulate with an Al2O3 content of 96 % or milling cylinders with an Al2O3 content of 98 %.

The grinding medias are available as balls with diameters from 7 to 63 mm and milling cylinders with a diameter from 13 to 45 mm. The focus of the development is the production of milling bodies of high quality with an aluminia content of more than 99 %.

Certification according to the new energy management system DIN ISO 50001

With an export share of 80 %, the company was able to remain an important player on the market even in economically challenging times. Its foundation are continuous diversification and quick adaptation of the product portfolio to the ever-changing requirements of the market.

Thus, employees were not made redundant in the economically critical year 2009. The team of 90 employees has remained largely unchanged over the last years.

In 2009, the company introduced the environmental management system according to DIN ISO 14001 and the integrated environmental, and energy management system according to DIN EN ISO 14001 and 50001 in 2012. This makes Kreutz grinding factory one of the companies that are certified according to the new energy management system DIN ISO 50001. The implementation of such a management system was urgent due to the high energy consumption of the milling and firing processes. Thus, monitoring and controlling of every energy-intensive systems with measurement technologies is possible. This is done with a large network of electricity meters that measure almost every system. This monitoring makes it possible to effectively identify energy-saving potential.

One important energy saving measure was the installation of a heat recovery system at the compressors that generate compressed air. Power of 1 MW is available at the compressors so that a large amount of waste heat is accumulated. This heat recovery system is in use since October 2012. This energy is used to heat processing water as well as all other heating systems in the production. This resulted in saving 25,000 m³ of natural gas up to now, and emission of 50 to of CO2 was avoided within 4 months.

Since the beginning of 2013, Ulrike Kreutz solely manages the business. As the daughter of the company’s founder, she has always been familiar with all production processes. With his respectable age, Helmut Kreutz is still part of the daily business. He constantly looks out for the latest developments in his company and is always a competent advisor with decades of experience.

In future, Helmut Kreutz GmbH managed by Ulrike Kreutz wants to maintain and further develop the existing production lines and sales volume in these challenging times for global economy. Flexibility and fast responses to client inquiries as well as the search for individual solutions are special strengths of the company. Stable turnover figures of over 80 million € per year speak for themselves.